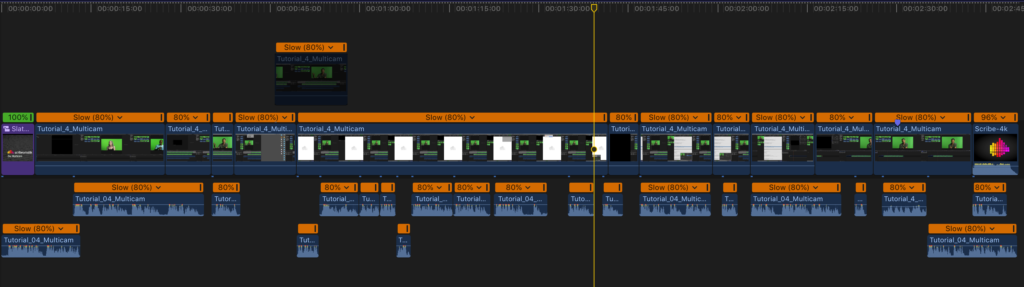

30p footage > 24p Project

Select All, Copy

Create New Project, 24p

Select All, “Automatic Speed” (80%), Ripple On

Select Vocal tracks, Custom Speed (80%), Ripple On

Alienorbit: Digital Content Tutorials

Tutorials for Digital Film Production, 3D Animation, Compositing and Video Editing

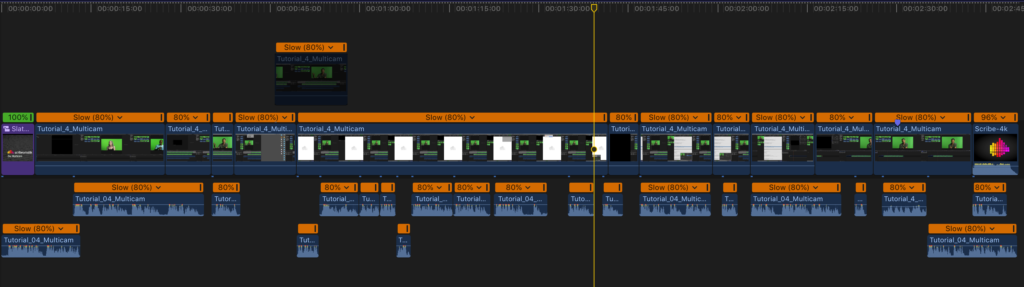

Select All, Copy

Create New Project, 24p

Select All, “Automatic Speed” (80%), Ripple On

Select Vocal tracks, Custom Speed (80%), Ripple On

We can use parametric modeling in Fusion 360 to generate the gear teeth, and adjust the inner diameter to match the focus diameter of the lens.

The simplest and fastest solution is the included gear script in Fusion 360 (it doesn’t indicate gear “module”(e.g. 32p), but as that is merely a reference number, it can be easily determined by the gear properties anyway).

Measuring Lenses

https://followfocusgears.com/pages/custom-gears

Common specs for cinema follow focus gear rings are 0.8 Module (32 Pitch), with more or less teeth depending on lens focus ring diameter and/or desired “resolution”.(You can create a lens ring wiht finer control by making the outer diameter larger, and a proper relative amount of teeth.

https://blog.misumiusa.com/understanding-gear-profile-and-gear-module/

https://blog.misumiusa.com/understanding-gear-profile-and-gear-module/

“Simplified, 48P, 32P, 0.8 mod, and 1.0 mod are measures of gear tooth size and are referenced to one inch or 25.4mm of pitch diameter. They express a ratio, with the P numbers being the numerator (top number) of the fraction and 25.4 being the denominator (bottom number) OR the mod values being the denominator and 25.4 being the numerator. So:

48P/25.4 = 0.5288m

32P/25.4 = 0.7938m

25.4/0.8m = 31.7653P

25.4/1.0m = 25.4P

I have listed them in order of ascending tooth size. Having larger teeth does lend more strength and a certain amount of mesh forgiveness, but it also reduces efficiency. On a severely overpowered Rustler or Bandit, switching to 32P/0.8 mod or even 1.0 mod may be necessary for spur gear longevity, but you’ll likely have to upgrade all other driveline parts before you must make the change.

I KNOW others will disagree. (And that’s O-KAY.)”

A solid tip that also works for round tripping color correction or VFX passes. Keep in mind that the “Export” page in Resolve is actuallycalled the “Deliver” page, and that’s where you find the

Easy to do.

Click the little arrow to reveal the Text options, alt / option click on the stopwatch icon, and past the following into the expression field.

thisComp.name

Slightly more advanced below.

https://zacklovatt.com/split-sourcetext-from-comp-name/